Precision Mechanics: The Role of Vacuum Seals in Modern Industry

In the world of meticulous engineering, the value of vacuum flanges is often underestimated. These crucial components play a key role in multiple industrial applications where the quality of a vacuum environment is paramount. From the manufacturing of semiconductors to the creation of materials in research laboratories, vacuum flanges serve as the core connective elements that ensure a secure and dependable seal. Without the effective use of vacuum flanges, numerous modern industrial processes would face major challenges that could jeopardize the quality and efficiency of production.

With industries moving forward to progress and push the boundaries of technology, the requirement for high-efficiency vacuum systems has grown. Vacuum flanges are engineered to withstand high pressures and temperatures, making them indispensable in environments that require exact control over atmospheric conditions. Whether it is in aerospace, pharmaceuticals, or chemical processing, these flanges allow manufacturers to sustain optimal vacuum levels, allowing critical operations that rely on a stable environment. In this article explore the various applications of vacuum flanges and explore their crucial role in advancing modern industrial practices.

Grasping Vacuum-Sealed Connectors

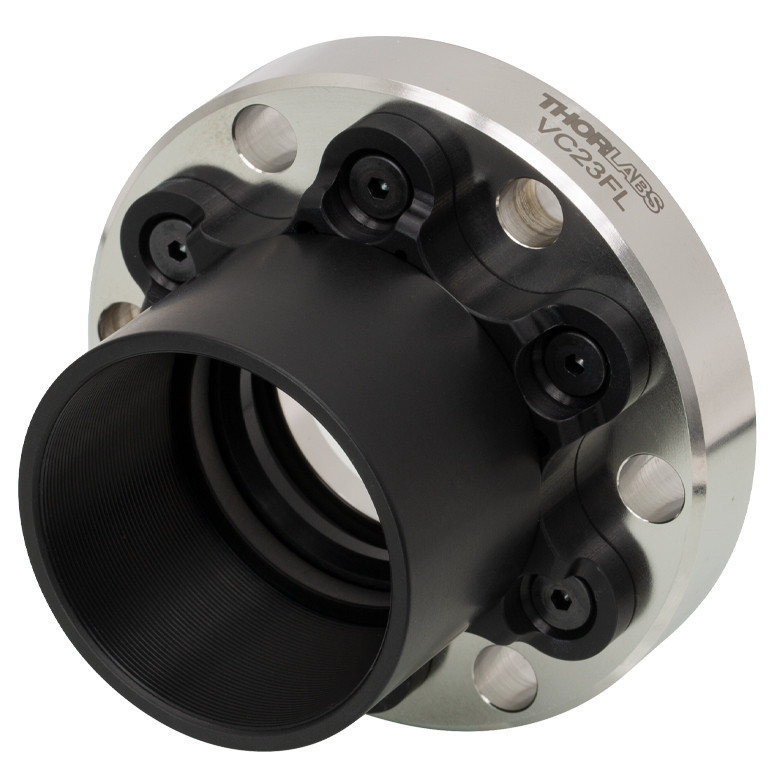

Vacuum-Sealed flanges are key parts in vacuum systems, acting as the connection interfaces for multiple components of the equipment. They allow the maintenance of a vacuum environment by providing airtight connections among various containers, guaranteeing limited gas leakage. This is particularly important in processes where impurities can compromise the outcomes, such as in semiconductor manufacturing, scientific research, and material fabrication.

Usually constructed from substances including stainless steel, aluminum, or ceramics, sealed connectors come in different standard sizes and shapes. The construction features channels and sealing surfaces that fit gaskets or O-rings to improve their connection capabilities. The selection of flange type and material is affected by the particular needs of the application, such as heat ranges, pressure levels, and chemical compatibility.

The proper installation and care of vacuum flanges are key for the effectiveness of vacuum environments. They have a vital role in reaching the desired vacuum levels while preventing outside contaminants from entering the system. Companies rely on premium vacuum connectors to ensure the integrity of their processes, making them critical in modern engineering and manufacturing practices.

Uses in Exact Engineering

Suction seals are essential to fine engineering, playing a key role in a number of industrial applications that demand managed environments. In fields like semiconductor manufacturing, suction seals provide the essential seal required to create and sustain ultra-clean vacuum conditions. This is vital for processes such as ion insertion and CVD, where even the slightest impurity can jeopardize product quality and performance. The capacity to maintain a stable suction pressure enables the precise control of material deposition and etching methods.

In the area of optical technology, vacuum seals are utilized to contain light systems that demand a vacuum to mitigate interference from environmental contaminants. This is crucial in situations such as laser cutting and substance processing, where accuracy is critical. By employing suction seals, fabricators can confirm that the path of the optical beam remains free from obstruction and well-directed, resulting in greater exactness and uniformity in manufacturing. This consistency directly affects the overall efficiency of manufacturing operations.

Furthermore, suction seals are essential in the development of high-performance vacuum chambers utilized in scientific investigation and development. These chambers enable experiments that demand harsh conditions, such as quantum physics and advanced matter research. The stability of the suction is preserved through the use of top-quality flanges, which ensure the necessary isolation from external environmental influences. This attention to specifics in the creation and use of vacuum seals greatly impacts the results of pioneering study and technical advancements.

Advantages of Vacuum Connectors in Manufacturing

Vacuum connectors play a critical role in maintaining the stability of vacuum systems across various industrial applications. Their capability to create a secure seal is vital for preventing gas leakage and sustaining the required vacuum levels. This strong sealing capability results in enhanced process efficiency and reliability, ensuring that equipment operates within optimized conditions. Consequently, sectors benefit from reduced contamination risks, which is particularly crucial in sectors like the semiconductor sector and pharmaceuticals.

An additional significant benefit of vacuum flanges is their compatibility with a broad range of materials and configurations. This flexibility allows industries to customize their vacuum systems to fulfill specific operational requirements. Various flange types, such as ISO, KF, and CF, provide options for varying pressure levels and temperature tolerances. This versatility makes it more convenient for engineers to design systems that not only fit the physical constraints of their facilities and adhere to performance standards within diverse applications.

Moreover, vacuum flanges contribute to safety measures and efficiency in manufacturing processes. Their robust construction helps prevent accidents that might arise from system failures due to leaks. By maintaining a secure connection between components, vacuum flanges minimize downtime caused by maintenance and repairs. This reliability translates into lower operational costs and enhances productivity, making vacuum flanges an indispensable part of modern industrial systems across various sectors.